Orifice Plate

A DIFFERENTIAL PRESSURE TYPE FLOW SENSING ELEMENT

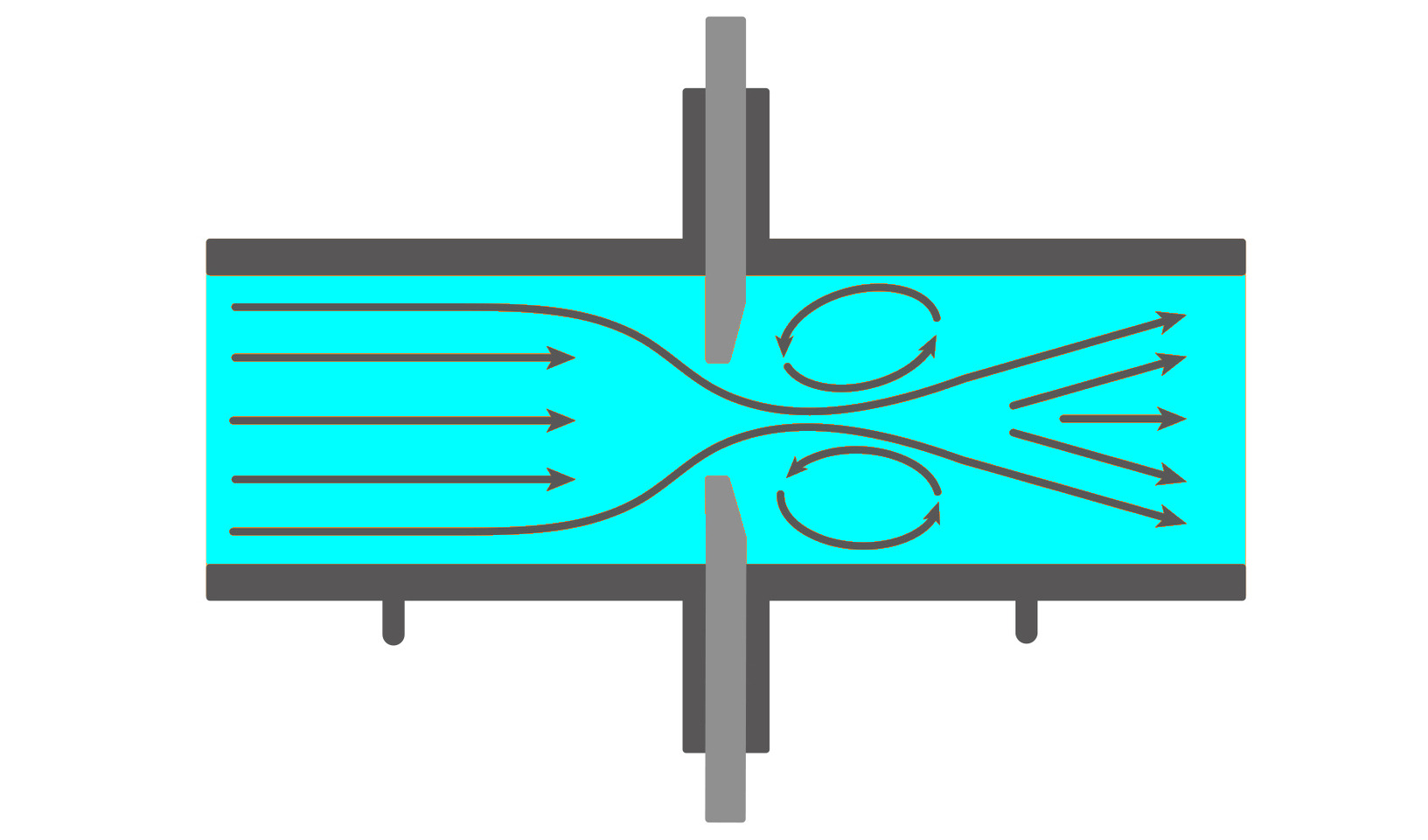

Orifice plates are most commonly used primary elements for flow measurement in pipelines based on the principle of measurement of ‘differential pressure’ created when an obstruction is placed in the fluid flow, due to increase in fluid velocity and decrease in pressure. It is one of the most common differential producer type flow elements for measuring clean liquids, gases, and low-velocity vapor (steam) flow. The difference in pressure is measured and converted into a DP flow measurement for a simple measurement solution. Their bore diameter is calculated to generate the specified differential pressure at full scale flow rate. This solution is widely used for gas, liquid and steam applications, including high temperature and high pressure environments. The technologies are field-proven and well suited for a variety of applications. The design offers optimum flexibility ideal for applications with many diverse existing piping schemes, and require considerably lower investment for the initial purchase of equipment. They give an acceptable level of uncertainties at lowest cost and long life without regular maintenance.

Although a number of different types of flow- rate measuring devices are available, the differential pressure type of flowmeter- orifice plate still makes up the largest segment of the total flow measurement market.

ME manufactures all types of orifice plate: square edged, conical entrance, annular, integral orifice assembly. And further distinguished as an orifice plate assembly with corner tappings, d & d/2 tappings, and flange tappings with or without carrier ring. Drain holes are provided as per standard and based on application. For larger pipe multiple tappings in the form of piezometric ring tappings are provided.

Method of calculation of orifice for a specific flow rate in a given size of pipe at a given pressure difference is based on and as prescribed and followed by international standards like bs1042,isa rp3.2, ISO 5167. Based on the standards me developed unique software calculator for orifice design incorporating data related to discharge coefficient, correction factor, expansibility factor, critical pressure ratio, critical flow factor, internal diameter of upstream pipe, pressure difference, density, viscosity, absolute pressure, absolute temperature, partial pressure of water vapor, specific heat ratio, Reynolds no, pressure loss, correction for thermal expansion etc.